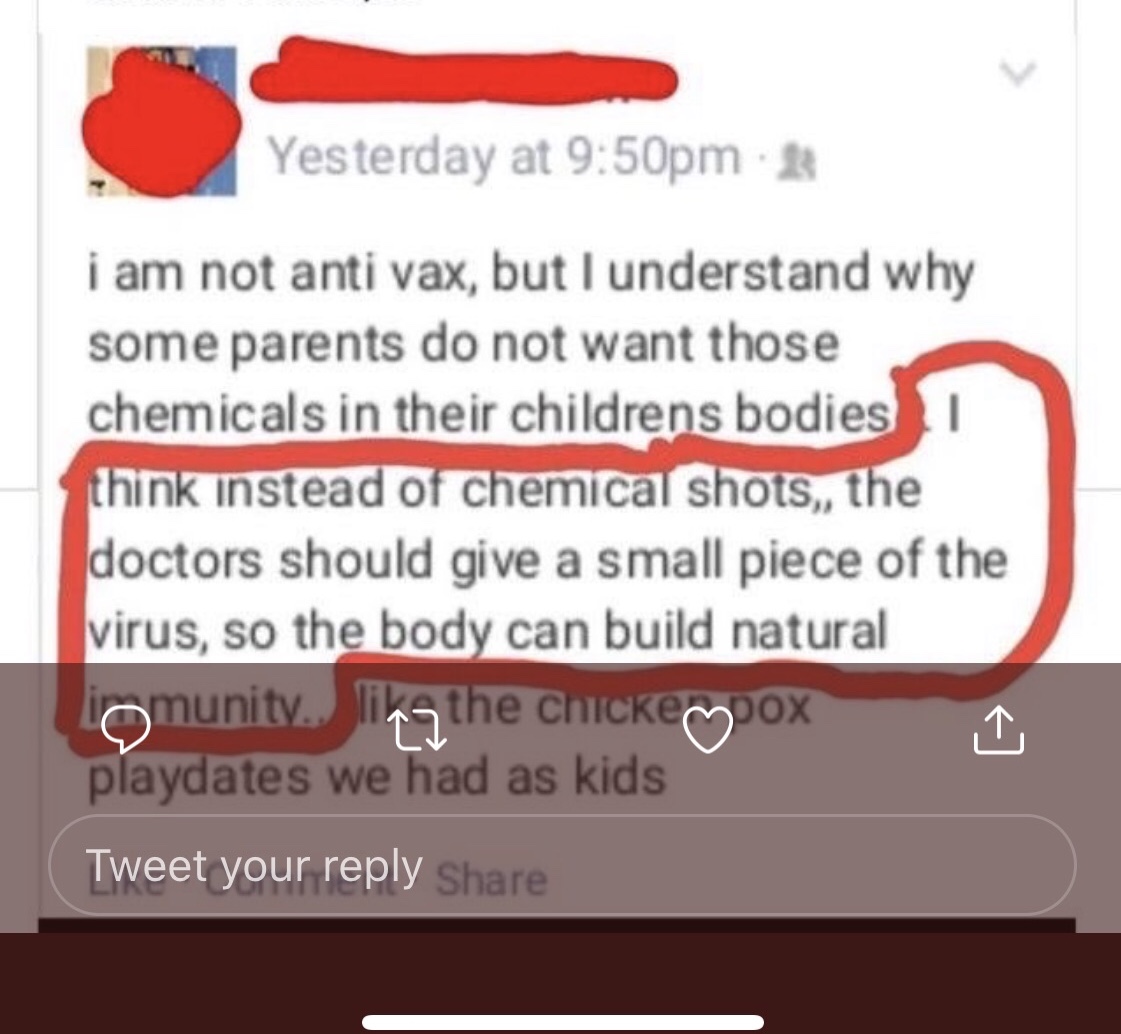

When I first saw this tweet, the snarky, judge-y part of me spoke up. “Well, duh. This is EXACTLY what vaccines do!” But I had to check myself, because judging and snark rarely, if ever, further understanding.

I have assumed (and you know what that does) that your average Joe or Jane knows how vaccines work and how they are made. I’m not sure why I thought this. It took many years of schooling – a science major in college, medical school, residency, and boots-on-the-ground clinical practice – to learn it myself.

Maybe part of the problem with vaccine-hesitancy these days is that people only know what they read from the very small but very vocal anti-vaccine camp. Perhaps all they hear about are chemicals and “toxins” and they don’t really understand what goes into making a safe and effective vaccine.

Well, I am here to offer a quick tutorial on the facts about how vaccines work and what goes into them. If you want further info (prepare for unabashed marketing plug), consider reading my book Let’s Talk Vaccines: A Clinician’s Guide to Addressing Vaccine Hesitancy and Saving Lives. Specifically the chapter titled: Vaccine ingredients – what is all that stuff anyway? While written for clinicians, it is easily grasped by your average Joe or Jane reader. Let’s begin.

How do vaccines work?

Vaccines are made in a couple of ways. Some take a virus or bacteria (those little buggers that make us so sick) and kill, inactivate, or seriously weaken them so that they are no longer able to cause illness. Some use a piece of virus or bacteria that, by itself, could not cause illness. The body then recognizes this whole or piece as foreign. It mounts an immune response which results in the production of antibodies. Antibodies are the patrols in our immune system, our body’s weapons, that scout for invaders and attack them before they can make us sick.

Image from Pixabay

The same process happens when we encounter a real, full blown illness, like measles or polio. We develop antibodies to keep us from getting sick the next time. The problem with developing antibodies from the real illness, is that the actual measles or polio infections bring with them significant risk for serious harm – hospitalization, paralysis, brain damage, pneumonia, blindness, death. Vaccines allow us to mount this immune response in a safe and controlled way, without putting ourselves at serious harm from deadly illness.

A reminder… Vaccines are not made against illnesses that are “no big deal”. There is no vaccine against the common cold, for example. Vaccines are made against diseases that have high costs, both in terms of long term health consequences and loss of life and also financial burden upon individuals, families, and society.

So, to sum up (and to quote Let’s Talk Vaccines), “instead of a surprise attack where all of our “troops” are ill-prepared for the onslaught and we suffer large losses in the battle; through vaccination, we are now equipped with weapons to defend ourselves, and our bodies are prepared to successfully fight off an attack.”

How are vaccines made?

So, we’re not going to talk about the research that goes into vaccines. You can read about that long and highly regulated process here. This is more of a discussion of how a vaccine is physically made. How is it manufactured? What all goes into a vaccine?

This will take us into a discussion about all the other “stuff” that’s in vaccines, apart from the actual virus or bacteria. This “stuff” is what seems to give many a vaccine-hesitant person heartburn. But we’ll learn that much of what is listed as a vaccine “ingredient”, is not actually in the vaccine and those things that are, are natural and safe.

Before we begin, let’s touch on a TRUTH about PACKAGE INSERTS. Hopefully, those capitalized letters got your attention.

1. Package inserts for vaccines require listing of any substance used in the manufacture of vaccines, whether it is in the final product or not. This would be like saying your oranges contain rubber because they were transported on a rubber conveyor belt while being packaged for sale.

2. Package inserts also require the listing of any event that was reported during testing of the vaccine, whether it is causally related to the vaccine or not. Case in point – teething. The Varivax product insert lists teething as an adverse reaction. Does anyone really believe that the Varivax vaccine induces teething? This is what we call “true, true, and unrelated” – a coincidence.

3. Let’s define some terms because this is important in interpreting the package insert.

a. Adverse Reaction – an adverse reaction is any event that happens in proximity to receiving a vaccine, whether causally related or not. For example, fainting. Some people faint after vaccines because of fear of needles and/or a vasovagal reaction. This is not necessarily caused by the vaccine. Let’s contrast this with an…

b. Adverse Event – these are events that follow a vaccination that are most likely caused by the vaccine. This would be things like a sore arm or short term body aches the day after your flu shot, for example. We know that the vaccine can cause these things.

4. The Adverse Reactions section of the product insert, therefore, lists things observed during testing but that may not be at all related to the vaccine. While the WARNINGS section is the spot where we need to look for things that were Adverse Events during testing.

**Note: you will find autism listed under Adverse Reactions (and we know that numerous studies looking at millions of children have shown no relation between vaccines and autism) but you will NOT find it in the Warnings section. Vaccines do not cause autism!

Ok, let’s move onto the steps of vaccine manufacture.

Image from Pixabay

Step 1: Growth

This is the mass production stage. First we have to grow the virus or bacteria or replicate the piece of virus or bacteria to be used.

What is required for growth? Well… some things you might expect.

1. A host – viruses and bacteria most often can’t grow without living in a cell. We need cell or tissue cultures to allow these buggers to multiply. This is where the chicken eggs, canine cells, yeast cells, or even human cells are used (See here for discussion of human cell lines used for vaccine production).

2. Nutrients – nothing can live without nutrition, right? Just like us, viruses and bacteria need…

a. Sugars – for example, dextrose and galactose

b. Salts – for example, potassium chloride and sodium pyruvate

c. Proteins – for example, soy peptone and bovine casein

d. Amino acids – for example, L-cysteine and L-histamine

e. Vitamins – for example, ferrous sulfate (iron) and magnesium sulfate

Image from Pixabay

Step 2: Processing and purification

Here is where we get rid of all the stuff that we don’t want in our vaccines.

First, processing.

1. Antibiotics – these are used during manufacture to prevent bacteria from growing in and contaminating the vaccine.

* These are most often antibiotics that are rarely allergy-inducing (like neomycin and polymyxin B). However, trace amounts may still remain in the end product. So people with allergic reactions to these substances should discuss with their medical provider whether these vaccines are safe for them (if a very mild reaction, the answer is probably “yes”).

2. Inactivating ingredients – these are used to kill or inactivate viruses or bacteria so that they can’t make us sick with the illness they are meant to protect against. In the purification stage, these substances are almost entirely removed from the vaccine.

* This includes substances like Formaldehyde (see here to learn about why Formaldehyde isn’t really that scary), glutaraldehyde (the amount remaining is <50 nanograms – that’s one billionth of a gram), and beta-propriolactone (present only in the anthrax vaccine – how many of us are getting that – and after placed in solution with water is completely broken down and harmless).

Isn’t science amazing? Yay, chemistry!

Next, purification

1. Protein purifiers – the purpose of these is to separate out the desirable proteins (the viral and bacterial parts) from the processing-related impurities discussed above (those used in growing the virus or bacteria).

* There are some long chemical names here. PS – don’t let the word “chemical” freak you out. We have come to think of “chemicals” as bad things – pesticides, plastics, etc. But all living things are made up of chemical compounds (remember the Periodic Table from school?). So the names of purification substances, like ammonium sulfate or hexadecyltrimethylammonium bromide, should not scare us.

Image from Pixabay

Step 3: Packaging the final product

So, we’ve grown our virus or bacteria (in whole or in part). We’ve processed out any impurities or contaminants. Now we have to make the final product – the stuff that goes in that vial we are all familiar with.

If you were making a vaccine for use across the world (considering need for transport and storage), what would it need to do? We’d need it to stay stable over time and not break down. It would need to stay in solution and not separate out. For vaccines that are multi-dose vials (accessed repeatedly to draw up the vaccine), it would have to resist growth of bacteria or fungi. We’d need it to withstand changes in temperature, acidity, humidity, and light. And we’d want to make it as effective as possible, inducing the strongest immune response that we can. The substances in the final vaccine product are there for exactly these reasons.

1. Adjuvants – These are added to “strengthen and lengthen” the immune response to vaccines. They are only used in killed or inactivated vaccines. They are not necessary in live-attenuated vaccines.

* For example, aluminum (see here for discussion of safety of aluminum), MF59 (Squalene oil – found naturally in humans, plants, and animals), and Xanthan (also found in toothpaste, gluten-free foods, and ice cream), among others.

2. Preservatives – these are used to prevent fungal or bacterial contamination of multi-dose vials.

* These include things like Thimerosal (now only present in multi-dose flu), Benzethonium chloride (only in anthrax vaccine currently but found more commonly in hand and body washes), and EDTA (also used as a chelating agent – meaning it binds metals and minerals to remove them from the body – and found in common household items like shampoo, contact solution, and cosmetics).

3. Stabilizers – These help keep the vaccine from breaking down when exposed to humidity, heat, light, and acidity. This is what keeps a vaccine potent over time.

* Gelatin, bovine albumin, human or recombinant human albumin (protein in the blood that has been screened for any infectious agents), casamino acids (made from casein in cow’s milk), and sorbitol (a naturally occurring substance in the human body and found in berries, often used as a sweetener), for example.

4. Buffers – substances that are used to preserve the acid-base balance (pH) of vaccines and is especially important in vaccines taken orally. It allows the vaccine to survive the acidic environment of the digestive tract. The can also decrease side effects like gas and bloating.

* Most commonly these are salts (such as sodium chloride and potassium chloride). Others you might recognize as ingredients in antacids (sodium bicarbonate and calcium carbonate).

5. Emulsifiers – also called surfactants, these are used to hold vaccine ingredients together so they don’t separate out. Just like adding mustard to your oil and vinegar salad dressing to keep the two together.

* Polysorbate 80 and 20 (used, respectively, in ice cream – the amount in the HPV vaccine, for example, is 50 mg compared to the 170,000 mg in ½ cup of ice cream – and cosmetics, sunscreens, baby oil, and others).

6. Residual proteins – very little if any of the substances used in manufacture of a vaccine remain in the final product. However, there are a few possible exceptions that bear mentioning.

* The Yellow Fever vaccine may contain some egg protein. Unlike other vaccines (like influenza) which no longer carry a contraindication for people who are egg-allergic, the yellow fever vaccine still does.

* HPV and Hepatitis B vaccines are grown in yeast cells and small amounts of residual yeast protein may remain. Anyone severely allergic to yeast (and this is very rare) should avoid these vaccines, at least until further study and recommendation.

7. Taste improvers – used only for oral vaccines. Basically, sugar.

8. Latex – this is not included in the vaccine itself but sometimes is present in the packaging. For example, some vials have a latex stopper. People with serious latex allergy (stopping breathing, for example) should ask about the packaging for each vaccine received.

Now we know what substances are used in vaccine manufacture and why. We know which ones end up in the final product and which are just used along the way, then purified out. Most of what is used we either already have in our bodies or it is in products that we use every day. We don’t think twice about them because they are familiar and we know them to be safe.